Descripción del producto:

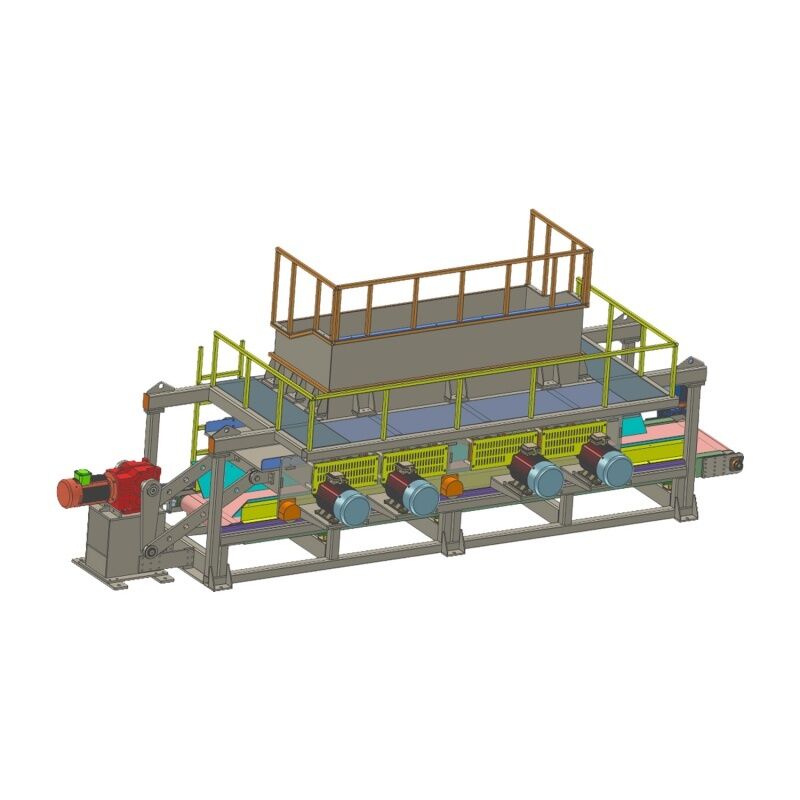

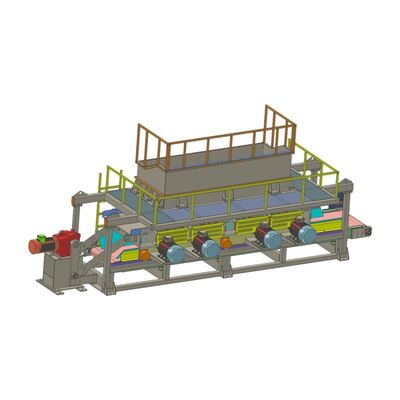

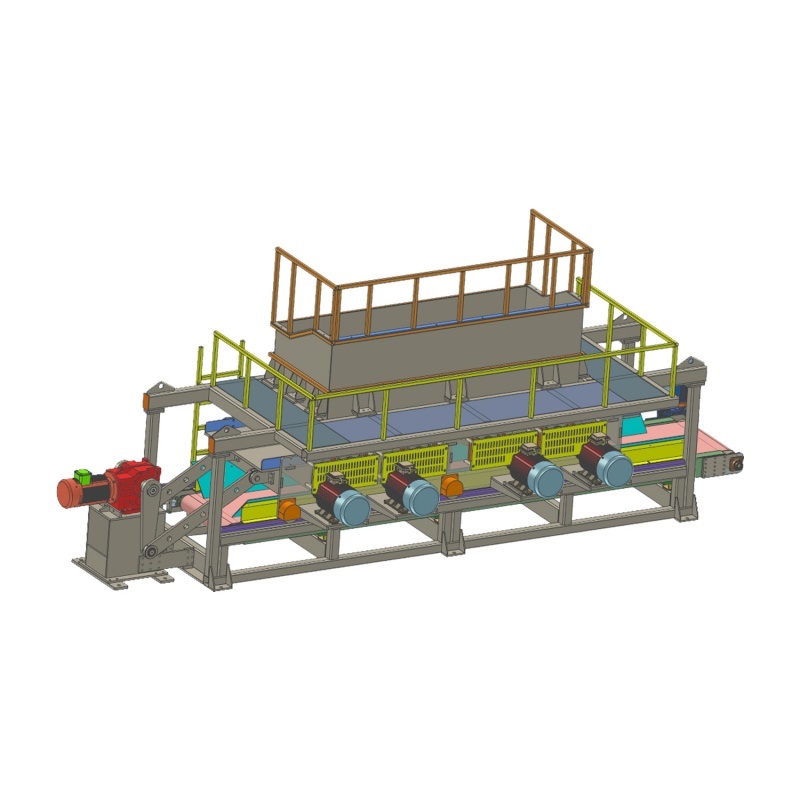

La máquina de afeitar la madera es un equipo industrial de última generación diseñado para procesar eficientemente la madera en astillas finas, lo que la convierte en una herramienta esencial para diversas aplicaciones en la elaboración de madera,Producción de combustibles de biomasaEsta máquina, impulsada por un robusto motor eléctrico, combina potencia, precisión y durabilidad para satisfacer las exigentes necesidades de las modernas instalaciones de procesamiento de madera.

Construido con componentes de acero y aleaciones de alta calidad, el molino de afeitar madera garantiza un rendimiento duradero y resistencia al desgaste.El uso de materiales de primera calidad no sólo mejora la durabilidad de la máquina, sino que también garantiza un funcionamiento estable incluso en condiciones de uso pesadoEsta construcción sólida permite a la máquina resistir las tensiones del funcionamiento continuo, lo que la convierte en una opción fiable para las empresas que buscan maximizar la productividad.

Una de las características destacadas de esta máquina hidráulica de afeitar madera es su funcionamiento automático de grado.la funcionalidad automática permite un control y un ajuste fluidos del proceso de afeitadoLos operadores pueden gestionar fácilmente el rendimiento de la máquina sin intervención manual, lo que reduce significativamente los costes laborales y aumenta la eficiencia operativa.Esta automatización también ayuda a mantener la calidad constante y la uniformidad de las astillas de madera producidas.

Con un peso de entre 800 kg y 8000 kg, la máquina de afeitar madera está disponible en varios modelos para adaptarse a diferentes escalas de producción y requisitos operativos.El rango de peso de la máquina refleja la versatilidad del productoA pesar de su tamaño considerable, la máquina está diseñada para facilitar la instalación y el mantenimiento.garantizar un tiempo de inactividad mínimo y una mayor productividad.

Con una capacidad de producción que oscila entre 200 kg y 4000 kg por hora, esta trituradora de madera es capaz de manejar de manera eficiente grandes volúmenes de materia prima de madera.Este impresionante rendimiento permite a las empresas escalar su producción según las demandas del mercado, garantizando un suministro constante de astillas de madera para diversos usos finales.

La máquina hidráulica de afeitar madera también está equipada con características de seguridad avanzadas y controles fáciles de usar, dando prioridad a la seguridad y la comodidad del operador.La integración de sistemas hidráulicos en la máquina no sólo mejora la precisión del proceso de afeitado, sino que también facilita ajustes más fáciles y ciclos de operación más rápidosEsta combinación de tecnología hidráulica y energía eléctrica da como resultado una máquina de alto rendimiento que cumple con estrictos estándares industriales.

Además de su función principal como molino de afeitar madera, esta versátil máquina también puede actuar como una trituradora de madera eficaz, que descompone trozos de madera más grandes en tamaños manejables antes de afeitar.Esta doble capacidad mejora su utilidad y lo convierte en una adición valiosa a cualquier instalación de procesamiento de maderaLa capacidad de realizar múltiples funciones reduce la necesidad de equipos adicionales, ahorrando espacio y costes de inversión.

En general, la máquina de afeitar madera es una solución poderosa, confiable y eficiente para todas las necesidades de afeitar y triturar madera.combinado con materiales de construcción de alta calidad y características operativas automáticas, garantiza un rendimiento y una longevidad superiores.Esta máquina ofrece la capacidad de producción y los avances tecnológicos necesarios para optimizar su flujo de trabajo de procesamiento de madera.

Invertir en esta máquina hidráulica de afeitar la madera significa adoptar la innovación, la durabilidad y la eficiencia, todo lo cual contribuye a una mayor productividad y rentabilidad.Su capacidad para procesar una amplia gama de materiales de madera con resultados consistentes lo convierte en una herramienta indispensable en la industria de procesamiento de maderaElija este molino de afeitar madera para experimentar la combinación perfecta de potencia, precisión y automatización en sus operaciones de procesamiento de madera.

Características:

- Nombre del producto: máquina de afeitar madera

- Peso de la máquina: 800 kg - 8000 kg, adecuado para operaciones de máquinas de afeitar madera a gran escala

- Componentes básicos: Motor, motor para un rendimiento fiable

- Material: Construido con componentes de acero y aleación de alta calidad para su durabilidad

- Las dimensiones: 5800 mm x 2100 mm x 2200 mm

- espesor de afeitado: ajustable de 0,2 mm a 0,5 mm o de 0,2 mm a 1 mm para satisfacer diferentes requisitos

- Ideal como máquina de afeitar madera para ropa de pollo y otras aplicaciones

- Máquina de forraje de madera eficiente diseñada para uso pesado en entornos industriales

Parámetros técnicos:

| Nombre del producto |

Máquina para afeitar madera |

| Aplicación |

Se utiliza en ropa de cama, envases y fabricación industrial |

| Características de seguridad |

Botón de parada de emergencia, cubiertas protectoras |

| espesor de afeitado |

0.2 mm - 0,5 mm o 0,2 mm - 1 mm |

| Fuente de energía |

Motor eléctrico |

| Capacidad de producción |

200-4000 kg/hora |

| El material |

Componentes de acero y aleaciones de alta calidad |

| Las dimensiones |

Se aplicará el método de ensayo de la norma de la Unión. |

| Grado automático |

Automático |

| Componentes básicos |

El motor, el motor |

Aplicaciones:

La máquina de afeitar madera SH, disponible en modelos como SHBH1000-4, SHBH600-4 y SHBH500-6, es una solución versátil y eficiente diseñada para diversas aplicaciones industriales y agrícolas.Originario de China y certificado CE, esta máquina de lana de madera está diseñada para producir astillas de madera de alta calidad con un grosor de afeitado ajustable que oscila entre 0,2 mm y 1 mm, lo que la hace ideal para múltiples escenarios de uso.

Una de las aplicaciones principales de la máquina de afeitar madera SH es en la ropa de cama de los animales.Los agricultores y los cuidadores de ganado utilizan las astillas de madera producidas por esta máquina de lana de madera para crear cómodos, absorbente e higiénica para animales como caballos, aves de corral y pequeños mamíferos.Las astillas de madera finas y consistentes generadas por la máquina ayudan a mantener un ambiente limpio al absorber eficazmente la humedad y reducir los olores, que promueve una mejor salud y bienestar de los animales.

Además de la ropa de cama de los animales, esta máquina de hacer astillas de madera se utiliza ampliamente en materiales de embalaje.Las astillas de madera sirven como material natural de amortiguación que protege los artículos frágiles durante el envío y manejoLas empresas que se centran en soluciones de embalaje ecológicas se benefician enormemente del uso de las astillas de madera producidas por el triturador de madera SH.ya que ofrece una alternativa biodegradable y sostenible a los rellenos de embalaje sintéticos.

Además, la máquina de afeitar madera SH se utiliza en diversos procesos de fabricación industrial.y otros productos compuestos de maderaSu control preciso sobre el grosor de afeitar (0,2 mm - 0,5 mm o hasta 1 mm) permite a los fabricantes adaptar las fibras de madera a requisitos específicos.mejorar la calidad y la consistencia de sus productos finales.

La seguridad y la eficiencia son primordiales en el diseño de la trituradora de madera SH. Equipada con un botón de parada de emergencia y tapas protectoras, la máquina garantiza la seguridad del operador durante el funcionamiento.Con dimensiones de 5800 mm*2100 mm*2200 mmLa máquina viene con embalaje luo y tiene un tiempo de entrega de aproximadamente 15-25 días.y la capacidad de suministro alcanza hasta 1000 juegos por año, que atiende a pedidos tanto a pequeña como a gran escala con una cantidad mínima de pedido de sólo 1 juego.La Comisión considera que la medida no constituye una ayuda estatal en el sentido del artículo 107 del Tratado..

¡Su mensaje debe tener entre 20 y 3.000 caracteres!

¡Su mensaje debe tener entre 20 y 3.000 caracteres! ¡Por favor revise su correo electrónico!

¡Por favor revise su correo electrónico!  ¡Su mensaje debe tener entre 20 y 3.000 caracteres!

¡Su mensaje debe tener entre 20 y 3.000 caracteres! ¡Por favor revise su correo electrónico!

¡Por favor revise su correo electrónico!